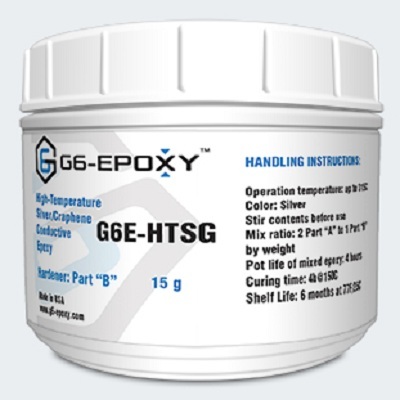

SILVER/GRAPHENE CONDUCTIVE EPOXY G6E-SG

Product Details:

- Color Silver

- Material Silver / Graphene filled epoxy

- Application epoxy

- Hardness >70 D

8000 INR/Pack

X

SILVER/GRAPHENE CONDUCTIVE EPOXY G6E-SG Price And Quantity

- 8000 INR/Pack

- 15 Gram

SILVER/GRAPHENE CONDUCTIVE EPOXY G6E-SG Product Specifications

- >70 D

- epoxy

- Silver

- Silver / Graphene filled epoxy

SILVER/GRAPHENE CONDUCTIVE EPOXY G6E-SG Trade Information

- Paypal

- 20 Days

- North America Eastern Europe Middle East Asia

- All India

- Technical Data sheets are available upon request

Product Description

Enter Buying Requirement Details

Other Products in 'Conductive Epoxy' category

|

ULTRANANOTECH PRIVATE LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |