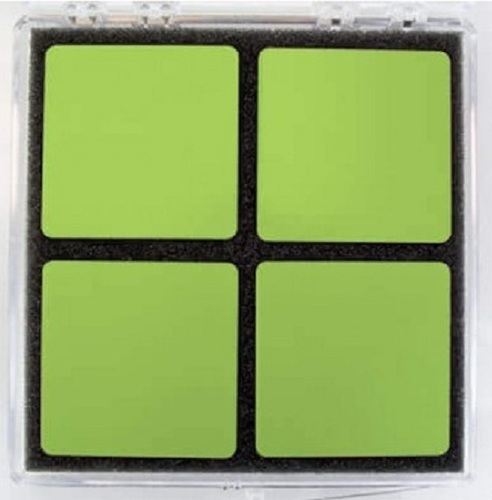

Solid Anode Electrolyte Planar Bi-Layer - 5 x 5cm

Solid Anode Electrolyte Planar Bi-Layer - 5 x 5cm Specification

- Purity

- >99.9%

- Hardness

- High mechanical strength, suitable for electrochemical applications

- Strength

- Excellent dimensional stability and durability

- Material

- Ceramic Electrolyte + Metal Oxide Anode

- Alloy

- None (pure material layers)

- Shape

- Other

- Moisture

- <0.5% (at packaging)

- Chemical Composition

- Anode layer: Metal oxide (e.g., Ni, Co, Fe based); Electrolyte layer: Ceria or YSZ-based solid electrolyte

- Application

- Solid oxide fuel cells (SOFC), electrochemistry research, materials testing

- Dimension (L*W*H)

- 5 cm 5 cm, thickness per layer typically 0.2-1 mm (customizable) Centimeter (cm)

- Color

- White (Electrolyte), Grey-Silver (Anode) Bi-layer format

- Porosity

- Optimized for ionic/electronic conductivity (<5%)

- Thermal Stability

- Up to 1200C in controlled environments

- Edge Quality

- Laser-cut, burr-free

- Resistance

- Low interfacial resistance

- Surface Finish

- Smooth and flat; ready for cell assembly

- Packaging

- Vacuum sealed, individually wrapped

- Electrolyte Layer Thickness

- Approx. 500-700 m (customizable)

- Shelf Life

- 12 months (recommended) in dry storage

Solid Anode Electrolyte Planar Bi-Layer - 5 x 5cm Trade Information

- Payment Terms

- Paypal

- Delivery Time

- 15 Days

- Main Domestic Market

- All India

About Solid Anode Electrolyte Planar Bi-Layer - 5 x 5cm

AnodeElectrolyte Planar Bi-Layer - 5 x 5cm

ProductCode: 6201614

Solid Oxide Fuel Cell (SOFC)Anode Electrolyte Planar Supported Bi-layer (AEB) cells are a great startingpoint for researchers wanting to work on low temperature cathode materials. TheAEB offers a ceria interface for the cathode layer to prevent zirconateformation.

Precision in Every Layer

Each anode-electrolyte bi-layer sheet is produced with precise thickness control and exceptional porosity optimization. The customizable design ensures optimal interface for advanced electrochemical performance, with laser-cut, smooth surfaces ready for immediate cell assembly. Such precision enhances reproducibility critical in research and industrial applications.

Reliable Thermal and Mechanical Stability

Manufactured to withstand temperatures up to 1200C, this bi-layer offers remarkable thermal resilience and mechanical robustness. High purity, strong dimensional stability, and low moisture (<0.5%) at packaging make it well suited for demanding solid oxide fuel cell applications and a variety of electrochemistry studies.

Quality Packaging and Longevity

Each sheet is individually vacuum-sealed to maintain purity and dryness, extending recommended shelf life to 12 months in dry storage. Burr-free edges, flat surfaces, and consistent dimensions (5 x 5 cm) simplify handling and integration, ensuring reliability from delivery to deployment in laboratory and industrial settings.

FAQ's of Anode Electrolyte Planar Bi-Layer - 5 x 5cm:

Q: How should the anode electrolyte planar bi-layer be handled and stored?

A: To maintain optimal performance, the bi-layer sheets should be handled with clean gloves to avoid contamination and stored in their vacuum-sealed packs in a dry environment. It is recommended to use the product within 12 months of packaging to ensure preserved properties.Q: What benefits does the planar bi-layer format provide for solid oxide fuel cell (SOFC) applications?

A: The bi-layer design delivers a robust interface with optimized porosity for enhanced ionic and electronic conductivity, while the high mechanical strength, low interfacial resistance, and precise edge quality support reliability and efficiency in SOFC assembly and testing.Q: When is customization of layer thickness available, and what range can be selected?

A: Customization is available at the ordering stage. The anode layer can be specified between 200-400 m, and the electrolyte layer between 500-700 m (or up to 1 mm upon request), allowing adaptation for various research or industrial needs.Q: Where can this bi-layered sheet be applied besides SOFC research?

A: In addition to SOFC development, the bi-layer is suitable for electrochemistry research, materials testing, and any application that requires high-purity planar metal oxide/ceramic interfaces-serving as a versatile substrate for scientists and manufacturers.Q: What process is used to ensure the bi-layer's low interfacial resistance and edge quality?

A: Laser-cutting technology forms smooth, burr-free edges and ensures dimensional accuracy. The interface is engineered for minimal resistance by optimizing layering and sintering conditions, which results in improved performance in electrochemical cells.Q: How does the packaging protect the materials, and what is its shelf life?

A: Each sheet is individually vacuum-sealed, preventing exposure to moisture or contaminants, which helps maintain high purity and performance. Under these protective conditions, the shelf life is recommended for up to 12 months in dry storage.Q: What advantages does the product's high purity and low moisture content provide?

A: Greater than 99.9% material purity and less than 0.5% moisture ensure consistent electrical properties, prevent degradation, and contribute to reliable results in sensitive electrochemical or materials research applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Fuel Cell products Category

1-Cell Rebuildable PEM Fuel Cell Kit

Hardness : Stainless steel (end plates): approx. 200 HV (Vickers Hardness)

Strength : Sufficient for educational and research use; withstands moderate clamping forces

Purity : N/A (Not applicable for assembled kit, but catalyst platinum purity typically >99.9%)

Shape : Other, Rectangular cell body with visible end plates

Product Type : Other, Single Cell Rebuildable PEM Fuel Cell Kit

Application : Other, Research, education, demonstration of PEM fuel cell technology

Tutorial Pro

Hardness : Soft

Strength : High

Purity : 99.99%

Shape : Other, Rectangular

Product Type : Other, Refractory Brick

Application : Other, Industrial Furnaces

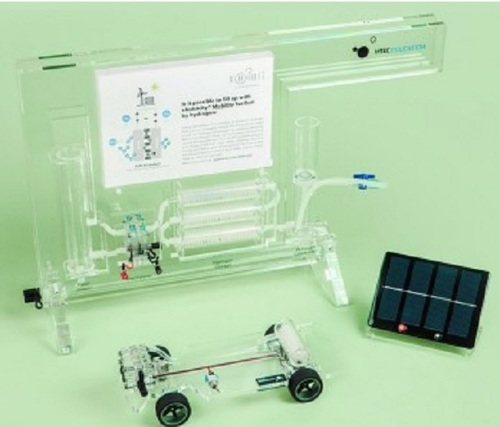

Fuel Cell Concept Car & Gas Station

Hardness : Not applicable (composite and metal structure used)

Strength : Reinforced structure for high impact resistance

Purity : 99.99% hydrogen for fuel cell operation

Shape : Other, Aerodynamic car body, rectangular station

Product Type : Other, Hydrogen fuel cell concept car and refueling station

Application : Other, Automotive transportation; demonstration of hydrogen infrastructure

Solar Hydrogen Demo Car and Gas Station

Hardness : N/A (Not specified for educational plastic components)

Strength : N/A (Demo model, not for loadbearing use)

Purity : N/A (Not applicable for demonstration model)

Shape : Other, Car: compact mini vehicle; Gas Station: rectangular station unit

Product Type : Other, Solar Hydrogen Demo Car & Gas Station Set

Application : Other, Demonstration, education, experiments in renewable energy and hydrogen fuel

|

ULTRANANOTECH PRIVATE LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry