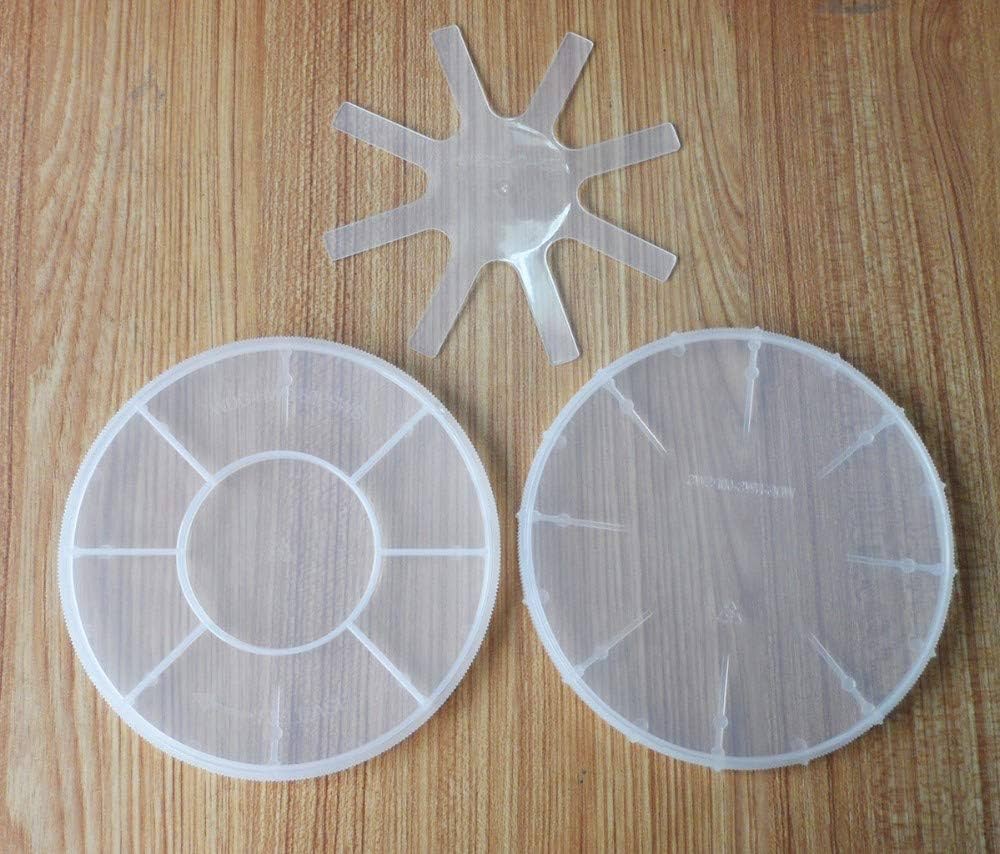

silicon wafer carrier box

Price 2301.0 INR/ Piece

silicon wafer carrier box Specification

- Product Name

- Silicon wafer carrier box

- Product Type

- Polypropylene

- Color

- white

- Application

- Silicon wafer storage

- Shape

- circular

silicon wafer carrier box Trade Information

- Minimum Order Quantity

- 3 Pieces

- Payment Terms

- Paypal

- Supply Ability

- 20 Pieces Per Day

- Delivery Time

- 5 Days

- Packaging Details

- seal pack

- Main Export Market(s)

- Asia

About silicon wafer carrier box

Diameter:2 inchSilicon Wafer Carrier Box

Introduction

A silicon wafer carrier box is a specialized storage and transportation container designed to safely hold silicon wafers during handling, storage, and shipment. These carrier boxes play a critical role in the semiconductor industry by protecting delicate wafers from physical damage, contamination, electrostatic discharge (ESD), and environmental exposure.

Silicon wafers are extremely sensitive to scratches, particles, and mechanical stress. The wafer carrier box ensures that wafers remain clean, intact, and properly aligned throughout manufacturing, research, and logistics processes.

Purpose and Importance

The primary purpose of a silicon wafer carrier box is to maintain wafer integrity from fabrication to final use. During semiconductor processing, wafers pass through multiple steps and locations, making secure handling essential.

Wafer carrier boxes help to:

-

Prevent wafer breakage and chipping

-

Minimize particle contamination

-

Reduce handling-related defects

-

Ensure safe transportation between cleanroom environments

-

Maintain proper wafer orientation and spacing

These boxes are widely used in semiconductor fabs, research laboratories, universities, and wafer distribution facilities.

Material and Construction

Silicon wafer carrier boxes are typically manufactured from high-purity, cleanroom-compatible plastics. Common materials include polypropylene (PP), polycarbonate (PC), and antistatic or conductive polymers.

Key construction features include:

-

Lightweight yet rigid structure

-

Antistatic or ESD-safe material options

-

Smooth internal slots to prevent wafer scratching

-

Secure locking mechanism or snap-fit lid

-

Chemical resistance to cleaning agents

Some carrier boxes are designed for repeated use and can withstand cleanroom cleaning and sterilization processes.

Types of Silicon Wafer Carrier Boxes

1. By Wafer Size

Carrier boxes are available for standard wafer sizes such as 2-inch, 3-inch, 4-inch, 6-inch, 8-inch, and 12-inch. Each box is precisely designed to match wafer diameter and thickness.

2. By Capacity

Carrier boxes can hold different numbers of wafers, commonly ranging from 1 wafer to 25 wafers per box. Research labs often use low-capacity boxes, while industrial applications prefer higher-capacity carriers.

3. By Environment

Cleanroom-grade wafer carrier boxes are designed to meet ISO cleanroom standards, while general-purpose boxes are used for non-critical storage and transport.

4. By Protection Level

Some carrier boxes provide basic physical protection, while advanced designs include enhanced ESD protection and sealing against moisture and dust.

Applications

Silicon wafer carrier boxes are used across various stages of semiconductor and materials processing, including:

-

Wafer manufacturing and fabrication facilities

-

Semiconductor device assembly units

-

Research and development laboratories

-

University and academic research centers

-

Safe shipment of wafers to customers and partners

They are also used for handling other fragile substrates such as glass wafers, quartz wafers, and sapphire wafers.

Advantages of Silicon Wafer Carrier Boxes

-

Protect wafers from mechanical damage

-

Reduce contamination and particle exposure

-

Improve handling efficiency and safety

-

Reusable and cost-effective

-

Available in multiple sizes and configurations

These advantages make wafer carrier boxes an essential accessory in semiconductor and research environments.

Purpose and Importance

The primary purpose of a silicon wafer carrier box is to maintain wafer integrity from fabrication to final use. During semiconductor processing, wafers pass through multiple steps and locations, making secure handling essential.

Wafer carrier boxes help to:

-

Prevent wafer breakage and chipping

-

Minimize particle contamination

-

Reduce handling-related defects

-

Ensure safe transportation between cleanroom environments

-

Maintain proper wafer orientation and spacing

These boxes are widely used in semiconductor fabs, research laboratories, universities, and wafer distribution facilities.

Material and Construction

Silicon wafer carrier boxes are typically manufactured from high-purity, cleanroom-compatible plastics. Common materials include polypropylene (PP), polycarbonate (PC), and antistatic or conductive polymers.

Key construction features include:

-

Lightweight yet rigid structure

-

Antistatic or ESD-safe material options

-

Smooth internal slots to prevent wafer scratching

-

Secure locking mechanism or snap-fit lid

-

Chemical resistance to cleaning agents

Some carrier boxes are designed for repeated use and can withstand cleanroom cleaning and sterilization processes.

Types of Silicon Wafer Carrier Boxes

1. By Wafer Size

Carrier boxes are available for standard wafer sizes such as 2-inch, 3-inch, 4-inch, 6-inch, 8-inch, and 12-inch. Each box is precisely designed to match wafer diameter and thickness.

2. By Capacity

Carrier boxes can hold different numbers of wafers, commonly ranging from 1 wafer to 25 wafers per box. Research labs often use low-capacity boxes, while industrial applications prefer higher-capacity carriers.

3. By Environment

Cleanroom-grade wafer carrier boxes are designed to meet ISO cleanroom standards, while general-purpose boxes are used for non-critical storage and transport.

4. By Protection Level

Some carrier boxes provide basic physical protection, while advanced designs include enhanced ESD protection and sealing against moisture and dust.

Applications

Silicon wafer carrier boxes are used across various stages of semiconductor and materials processing, including:

-

Wafer manufacturing and fabrication facilities

-

Semiconductor device assembly units

-

Research and development laboratories

-

University and academic research centers

-

Safe shipment of wafers to customers and partners

They are also used for handling other fragile substrates such as glass wafers, quartz wafers, and sapphire wafers.

Advantages of Silicon Wafer Carrier Boxes

-

Protect wafers from mechanical damage

-

Reduce contamination and particle exposure

-

Improve handling efficiency and safety

-

Reusable and cost-effective

-

Available in multiple sizes and configurations

These advantages make wafer carrier boxes an essential accessory in semiconductor and research environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Silicon Wafer Category

Silicon Wafer Diameter Intrinsic (4-inch)

Price 4000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Silicon

Product Name : Silicon Wafer Diameter Intrinsic (4inch)

Color : Grey

Product Type : Wafer

2 inch Intrinsic Silicon Wafer

Price 2500.0 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Single Crystal

Product Name : Silicon Wafer Intrinsic: Diameter2 inch

Color : Shinning grey

Product Type : Intrinsic

4inch N Type Silicon Wafer

Price 4648.0 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Single Crystal

Product Name : Silicon Wafer N Type : Diameter 4 inch

Color : Shinning grey

Product Type : N Type

Silicon Wafer P Type : Diameter-2 inch

Price 2000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Single Crystal

Product Name : Silicon Wafer P Type : Diameter2 inch

Color : Shinning grey

Product Type : P Type

|

ULTRANANOTECH PRIVATE LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry