Junior Basic

Junior Basic Specification

- Purity

- 98% min

- Strength

- High tensile strength

- Hardness

- Solid

- Product Type

- Refractory bricks

- Material

- Basic refractory

- Alloy

- No

- Shape

- Rectangular

- Moisture

- Nil

- Chemical Composition

- Standard composition

- Application

- Lining of furnaces, kilns, fireboxes, and fireplaces

- Dimension (L*W*H)

- 24 x 12 x 6 cm

- Color

- Grey

- Usage Environment

- High temperature industrial applications

- Porosity

- 18-22%

- Refractoriness

- Above 1500°C

- Bulk Weight

- 2.8 kg/brick

- Abrasion Resistance

- Excellent

- Water Absorption Rate

- 15-18%

- Standard Packaging

- Wooden pallet with shrink wrap

- Thermal Conductivity

- Low

- Density

- 2.2 - 2.4 g/cm³

Junior Basic Trade Information

- Payment Terms

- Paypal

- Delivery Time

- 15 Days

- Main Export Market(s)

- Australia, North America, Eastern Europe, Central America, South America, Asia

- Main Domestic Market

- All India

About Junior Basic

Junior Basic

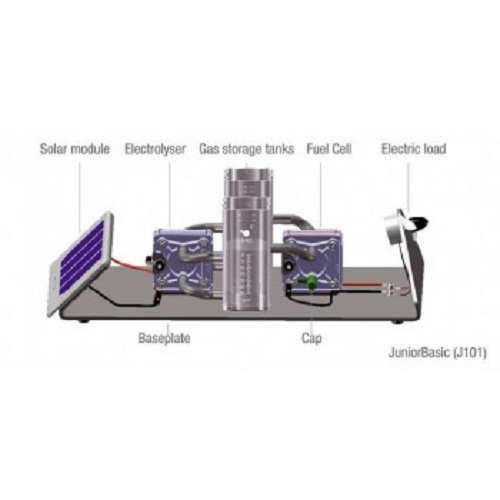

Brand: H-TEC Education

Product Code: 1071006

Description:

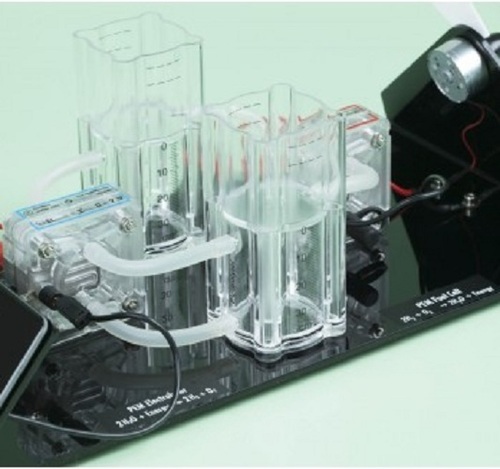

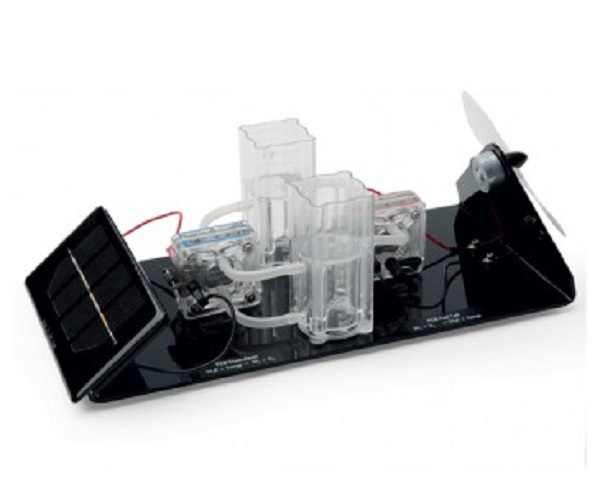

H-TEC's Junior Basic, J101 is a Solar Hydrogen Experimentation System consisting of solar module, PEM Electrolyser, hydrogen and oxygen storage tanks, PEM fuel cell and fan (for electric load); mounted on a black base-plate, and textbook. The included H-TEC Education fuel cell textbook contains information about the technology and instructions for a variety of experiments.

The Junior Basic reflects the simple elegance of the hydrogen cycle by reflecting a self-contained hydrogen system that is perfect for introducing the technology behind the solar hydrogen cycle, or for small demonstrations

Features:

- Compact system on one base-plate

- Clear, self-explanatory set-up

- Sturdy construction

- Short setup time

- Electrolyzer Cell 5

- x2 Storage 30

- Fuel Cell Hydrogen Oxygen

- Solar Panel Cell

- Fan Load

- Acrylic Base Plate

- Instructional Textbook

- Producing and storing hydrogen and oxygen

- Determining characteristic curve of solar panel

- Operating the fuel cell with hydrogen and oxygen 2:1

- Determining characteristic curve of electrolyser

- Determining electrolyser efficiency

- Learning about Faraday's laws

- Determining characteristic curves of fuel cell

- Determining fuel cell efficiency

- Determining decomposition voltage of water

- Storing electrical energy from wind by using hydrogen technology

- Demonstrating a complete renewable hydrogen energy system

Exceptional Durability for High-Temperature Settings

Junior Basic bricks are engineered to withstand extreme heat, with a refractoriness exceeding 1500C. Their excellent abrasion resistance and high tensile strength make them ideal for intensive tasks in industrial furnaces and kilns. Their robust structure and solid hardness ensure durable, long-lasting performance even in the most challenging operating environments.

Optimized for Efficient Heat Management

Thanks to low thermal conductivity and controlled porosity (18-22%), these bricks provide effective insulation and thermal stability. Their reliable bulk weight and minimized moisture content allow for optimal energy efficiency and reduction of heat loss, making them essential for high-temperature industrial processes.

Quality Assurance and Convenient Supply

Every Junior Basic brick meets strict manufacturing standards that guarantee a minimum purity of 98% and no moisture. They come in standard rectangular shapes and are shipped in secure wooden pallets with shrink wrap for safe handling and transportation. The bricks are widely available through distributors, manufacturers, and retailers across the United States.

FAQ's of Junior Basic:

Q: How should Junior Basic bricks be installed for lining industrial furnaces?

A: Junior Basic bricks should be installed by aligning them in a staggered pattern using suitable refractory mortar to ensure a tight seal. It is recommended to follow the proper installation guidelines for refractory linings to maximize durability and heat resistance.Q: What benefits do Junior Basic bricks offer in high-temperature applications?

A: These bricks provide excellent abrasion resistance, high tensile strength, and low thermal conductivity, making them highly efficient in conserving energy and protecting industrial assets under extreme thermal and mechanical stress.Q: When is it ideal to use Junior Basic bricks in a project?

A: Junior Basic bricks are best used in applications where continuous exposure to temperatures above 1500C and significant mechanical wear are expected, such as the lining of furnaces, kilns, fireboxes, and industrial fireplaces.Q: Where are Junior Basic bricks typically supplied in the United States?

A: They are distributed, manufactured, and supplied to industrial suppliers, contractors, and end-users across the United States through an established network of distributors, retailers, and traders.Q: What process ensures the quality and purity of Junior Basic bricks?

A: Strict quality control protocols are followed during manufacturing to achieve a purity of at least 98%, with standard chemical composition and solid hardness. Each batch is tested for density, refractoriness, porosity, and moisture content before packaging.Q: How does the low thermal conductivity of these bricks affect usage?

A: Low thermal conductivity minimizes heat loss and improves energy efficiency in high-temperature environments, providing better insulation for furnace linings and prolonging the operational life of the equipment.Q: What is the standard packaging process for Junior Basic bricks during distribution?

A: Junior Basic bricks are securely stacked on wooden pallets and sealed with shrink wrap, ensuring they remain intact and protected during transportation and storage.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Fuel Cell products Category

Microbial H-Cell (100 mL)

Material : Borosilicate Glass, Glass Frit

Product Type : Other, HCell Reactor for Microbial/Electrochemical Applications

Color : Transparent with Clear View

Shape : Other, HType (Dual Chamber Cylinder Joined With Bridge)

Dimension (L*W*H) : Cylinder Sections; Each side approx. 8 cm Height, 5.5 cm Diameter (Total Volume 100 mL)

Application : Other, Microbial Fuel Cell Studies, Bioelectrochemistry, Laboratory R&D, Electrochemical Experiments

Solar USB 2.0 Kit

Material : Monocrystalline silicon panel, ABS body

Product Type : Other, Solar USB Charging Kit

Color : Black

Shape : Other, Rectangular

Dimension (L*W*H) : 120mm x 80mm x 30mm

Application : Other, Charging USB devices using solar energy

Microbial H-Cell (1 L)

Material : Highquality borosilicate glass, Polypropylene

Product Type : Other, Microbial HCell (1 L)

Color : Transparent (Clear Glass); Black (Central Cap And Sleeves)

Shape : Other, Cylindrical main chambers with flat bottom

Dimension (L*W*H) : Length: Approx. 17 cm; Diameter: Approx. 10 cm; Volume: 1 L total

Application : Other, Electrochemical research, microbial fuel cell studies, biochemistry experiments

Renewable Energy Exhibition Set

Material : Acrylic, ABS, metal, and electrical parts

Product Type : Other, Exhibition demonstration model

Color : Multicolor (as shown in image)

Shape : Other, Rectangular set with modular components

Dimension (L*W*H) : 120 cm x 60 cm x 100 cm (approx.)

Application : Other, Educational, Renewable Energy Awareness, Exhibition Demo

|

ULTRANANOTECH PRIVATE LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry