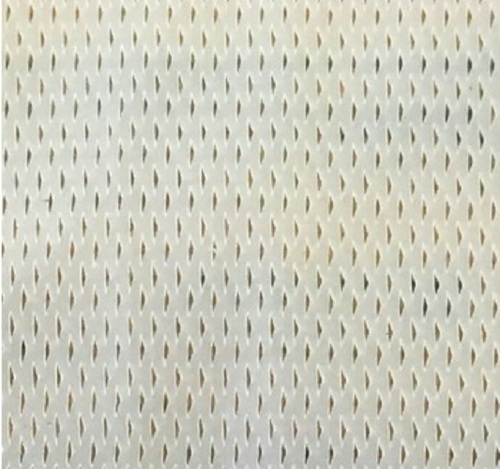

PTFE Turbulence Promoter Mesh

PTFE Turbulence Promoter Mesh Specification

- Material

- PTFE (Polytetrafluoroethylene)

- Application

- Used as turbulence promoters in filtration, separation, and purification systems

- Chemical Composition

- Polytetrafluoroethylene (PTFE), (C2F4)n

- Shape

- Mesh

- Hardness

- Shore D 50-60

- Density

- 2.3 Gram per cubic centimeter(g/cm3)

- Color

- Opaque White

- Mesh Size

- Customizable as per application

- Compliance

- FDA & USP Class VI compliant (if requested)

- Surface Finish

- Smooth, low friction

- Chemical Resistance

- Excellent resistance to most chemicals and solvents

- Length

- Available in rolls or cut-to-size

- Tensile Strength

- 2135 MPa

- Water Absorption

- Nil

- Thickness

- Typically 0.2 mm to 2 mm

- Flammability

- Non-flammable

- Temperature Resistance

- -200C to +260C

- Width

- Available in standard or custom widths

PTFE Turbulence Promoter Mesh Trade Information

- Payment Terms

- Paypal

- Delivery Time

- 15 Days

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

About PTFE Turbulence Promoter Mesh

PTFETurbulence Promoter Mesh

ProductCode: 72500424

This PTFE turbulencepromoter mesh can be pulled and stretched to accommodate irregular shapeswithout fraying. It is often used in ovens and dryers. It is excellent withalmost all acids, bases, fats, and organic solvents.

The indicated thickness values are for the uncompressed state. Undercompression, there will be a slight reduction in the thickness of the meshproducts due to flattening of the wires from wavy form to straight form, thoughthis is not a permanent feature. As soon as the compression force istaken away, the mesh products go back to their original thickness values.

Outstanding Chemical and Temperature Resistance

The PTFE Turbulence Promoter Mesh delivers high-performance resistance against a broad range of chemicals and solvents. With its wide operating temperature (-200C to +260C), it maintains stability and integrity even in harsh environments, making it suitable for demanding industrial applications.

Flexible Customization and Application Versatility

Available in customizable mesh sizes, widths, and thicknesses, the PTFE mesh can be tailored to specific requirements. Whether in rolls or cut-to-size formats, it integrates effortlessly into filtration, separation, and purification systems, supporting diverse operational needs.

FAQ's of PTFE Turbulence Promoter Mesh:

Q: How is PTFE Turbulence Promoter Mesh implemented in filtration and separation systems?

A: PTFE Turbulence Promoter Mesh is installed within filtration, separation, or purification equipment to promote turbulent flow. This enhances mixing and contact between materials, improving efficiency and effectiveness in liquid or gas processing environments.Q: What advantages does the mesh's chemical resistance provide for industrial applications?

A: Thanks to its excellent chemical resistance, the PTFE mesh withstands exposure to most acids, bases, and solvents, ensuring longevity and reliability in challenging operational conditions without degrading or contaminating the processed media.Q: When should custom mesh size or format options be selected?

A: Custom mesh size, width, or thickness are chosen when standard sizes do not meet specific system requirements. Customizing the mesh ensures optimal turbulence, improved process performance, and seamless fit within equipment design constraints.Q: Where can PTFE Turbulence Promoter Mesh be sourced in the United States?

A: The product is distributed, manufactured, retailed, and supplied by authorized companies throughout the United States. It can be ordered directly from manufacturers, distributors, or specialized industrial suppliers and traders.Q: What is the process for ordering FDA & USP Class VI compliant PTFE mesh?

A: To obtain mesh with FDA and USP Class VI compliance, specify this requirement during ordering. Manufacturers will supply the mesh with appropriate certification to ensure suitability for regulated environments, such as pharmaceutical or food processing applications.Q: How does the mesh's low friction surface benefit system performance?

A: The smooth, low friction surface reduces drag and fouling within systems, enabling efficient flow and decreasing maintenance needs. This trait is especially valuable in continuous operation processes involving sticky fluids or fine particulates.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Fuel Cell Membranes Category

MEA AEM Durion LMW 30I m 0.5mgPt Cloth

Material : Durion LMW Cloth with Platinum (Pt) Catalyst

Chemical Composition : Low Molecular Weight Durion, Supported Platinum (0.5 mg/cm)

Application : Electrochemical Devices, Fuel Cells, Electrolyzers

Shape : Rectangular Flat Sheet/Cloth

Density : 1.8 Gram per cubic centimeter(g/cm3)

Hardness : Flexible, Nonrigid

Pention-AEM-72-05-15 Crosslinking

Material : AEM (Ethylene Acrylate Rubber)

Chemical Composition : Ethylene acrylate copolymer with crosslinking agent

Application : Crosslinking agent for automotive and industrial rubber parts

Shape : Sheets/strips

Density : 1.25 Gram per cubic centimeter(g/cm3)

Hardness : 72 Shore A

Fumasep FKS-PET-130

Material : Perfluorosulfonic acid/PTFE copolymer cast on PET support

Chemical Composition : Perfluorosulfonic acid polymer reinforced with PET

Application : Proton Exchange Membrane Fuel Cells, Electrolyzers, Electrochemical Cells

Shape : Flat sheet membrane

Density : 2.1 Gram per cubic centimeter(g/cm3)

Fumasep FAP-450

Material : Perfluorinated Anion Exchange Membrane (AEM)

Chemical Composition : Perfluorinated polymer with quaternary ammonium functional groups

Application : Fuel cell, Electrolyzers, Electrochemical applications

Shape : Flat Sheet Membrane

Density : 2.0 Gram per cubic centimeter(g/cm3)

|

ULTRANANOTECH PRIVATE LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry