Aquivion E98-15S

Aquivion E98-15S Specification

- Material

- Perfluorosulfonic Acid (PFSA) ionomer membrane

- Application

- Fuel cells, electrolyzers, electrochemical applications

- Chemical Composition

- Equivalent weight 980 g/eq. (E98 series), Sulfonic acid-functionalized tetrafluoroethylene-based fluoropolymer

- Shape

- Membrane sheet

- Hardness

- Not specified (flexible solid film)

- Density

- 2.1 Gram per cubic centimeter(g/cm3)

- Trade Name

- Aquivion E98-15S

- Proton Conductivity (at 25C, 100% RH)

- >0.08 S/cm

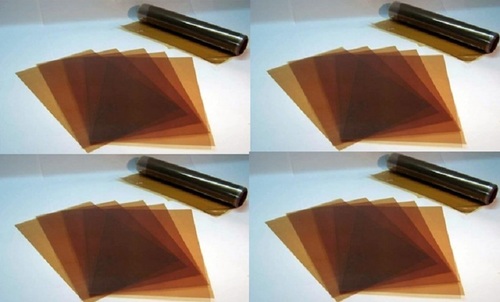

- Color

- Colorless to light opaque

- Thickness

- 15 m

- Tensile Strength

- 20 MPa (dry)

- Form

- Rolls or cut sheets

- Operating Temperature Range

- Up to 100C (dependent on application)

- Water Uptake (at 25C, 100% RH)

- 12%-18%

- Equivalent Weight (EW)

- 980 g/eq.

Aquivion E98-15S Trade Information

- Payment Terms

- Paypal

- Delivery Time

- 15 Days

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

About Aquivion E98-15S

Brand: Solvay Specialty Polymers USA

Product Code: 72700012

Aquivion membrane is used to separate the anode andcathode compartment of proton exchange membrane fuel cells (PEMFCs) and waterelectrolyzers, separators for electrochemical hydrogen pump or redox flowbatteries, and pervaporation or gas humidification systems. Various other electrochemicaltechnologies can also benefit from Aquivion membranes. Aquivion E98-15Smembrane has a nominal thickness of 150 micrometers ( 5.9 mil), which makes itsuitable for unpressurized or pressurized H2/Air PEMFCs, unpressurized orpressurized H2/O2 PEMFCs, unpressurized or pressurized water electrolyzers,unpressurized or pressurized electrochemical hydrogen pumps, redox flowbatteries, pervaporation or gas humidification systems, etc. Direct methanolfuel cells (DMFCs), direct ethanol fuel cells (DEFCs), and various otheralcohol based fuel cells can also benefit greatly from this cation exchangemembrane.

Solvay Aquivion E98-15S is a perfluorosulfonic acid(PFSA) ionomer membrane that exhibits an equivalent weight (EW) of 980 g/eg.Aquivion PFSA ionomer membranes are melt-extruded products based on the uniqueShort Side Chain copolymer of Tetrafluoroethylene (TFE) and Sulfonyl FluorideVinyl Ether (SFVE) F2C=CF-O-CF2CF2-SO2F produced by Solvay. This membrane isavailable in the acid form (H+) and features a lower EW than most commercialproton exchange membranes or cation exchange membranes. The unique Short SideChain copolymer allows higher crystallinity, improved mechanical properties,and better proton conductivity. Aquivion E98-15S membrane is anon-reinforced membrane based on the chemically stabilized Solvay PFSA ionomer,which exhibit substantially lower fluoride ion release compared to thenon-stabilized polymer a sign of improved chemical durability. Chemicalstabilization process is also known as end group conversion in which a largeamount of polymer end groups are converted to their inert "CF3"configuration, and as such provides excellent lifetime. Aquivionmembranes are also manufactured in the standard form without the chemicalstabilization. The polymer is chemically resistant and durable forvarious electrochemical and non-electrochemical applications.

Key Advantages:

Very high concentration of functional groups for strongproton (or Na+, K+, Li+, etc.) conductivity

High softening point for high temperature operation well above 80 C

Strong water retention for better fuel cell operation at low-humidityconditions

Comparison of Short Side Chain and Long Side ChainPFSA Membranes:

Aquivion PFSAs shorter side chain makes itpossible to achieve either better mechanical properties at the same IEC(ion-exchange capacity) or a higher IEC at the same mechanical properties thanlong side chain polymers (LSC). A comparison of Short Side Chain and LongSide Chain PFSA polymers from a polymeric composition is provided in thefollowing image.

High Performance in Demanding Applications

Aquivion E98-15S membrane stands out in the field of electrochemical energy due to its superior proton conductivity and mechanical stability. Suitable for use in a broad temperature range up to 100C, it is especially valued in fuel cell and electrolyzer systems for both efficiency and durability. Its ability to perform under rigorous conditions makes it a go-to choice for engineers and manufacturers seeking reliability.

Flexible Forms for Varied Installations

Available as either rolls or custom-cut sheets, Aquivion E98-15S adapts easily to different installation requirements. This flexibility streamlines your production process, ensuring a precise fit for various system designs. The membrane's shape and handling advantages translate to time and cost savings during assembly.

FAQ's of Aquivion E98-15S:

Q: How should Aquivion E98-15S membrane be handled during installation?

A: It is recommended to handle Aquivion E98-15S carefully, using gloves and clean tools to prevent contamination. The membrane's flexible, solid-film structure allows for simple cutting and fitting within your system, whether from rolls or precut sheets.Q: What is the primary benefit of using Aquivion E98-15S in fuel cell applications?

A: The key advantage is its high proton conductivity combined with robust mechanical strength, enabling improved efficiency, reliability, and operational life in fuel cells and related electrochemical devices.Q: When is Aquivion E98-15S most suitable for electrochemical applications?

A: Aquivion E98-15S is best utilized when high proton transfer, mechanical durability, and chemical stability are critical, particularly in systems operating at temperatures up to 100C and high humidity environments.Q: Where can Aquivion E98-15S membranes be sourced in the United States?

A: Aquivion E98-15S is available through authorized distributors, manufacturers, suppliers, and retailers across the United States who specialize in advanced membrane materials for electrochemical applications.Q: What is the process for integrating Aquivion E98-15S into fuel cell stacks?

A: The membrane can be integrated by cutting it to match the stack design, followed by lamination or assembly with electrodes and other layers according to the specific architecture and sealing requirements of your system.Q: What kinds of water uptake can users expect from Aquivion E98-15S?

A: At 25C and 100% relative humidity, Aquivion E98-15S demonstrates a water uptake of 12% to 18%, which contributes to its high proton conductivity and stable operation under hydrated conditions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Fuel Cell Membranes Category

MEA PEM Dyneon 725 05I m 0.5mgPt Cloth

Chemical Composition : Perfluorosulfonic acid membrane (Dyneon 725) with platinum catalyst (0.5 mg/cm) supported on carbon cloth

Density : 2.0 Gram per cubic centimeter(g/cm3)

Application : Proton Exchange Membrane Fuel Cells (PEMFC), Hydrogen Electrolyzers, Electrochemical cells

Shape : Sheet/Cloth

Material : PEM (Proton Exchange Membrane) with Dyneon 725 and platinum catalyst on cloth backing

Hardness : Soft, flexible membrane

Polypropylene Turbulence Promoter Mesh

Chemical Composition : Polypropylene homopolymer (C3H6)n

Density : 0.90 Gram per cubic centimeter(g/cm3)

Application : Turbulence promoter for filter cartridges, cooling towers, water treatment systems, and chemical processing applications

Shape : Mesh/Grid

Material : Polypropylene

Hardness : Shore D 78

MEA AEM Durion LMW 30I m 0.5mgPt Cloth

Chemical Composition : Low Molecular Weight Durion, Supported Platinum (0.5 mg/cm)

Density : 1.8 Gram per cubic centimeter(g/cm3)

Application : Electrochemical Devices, Fuel Cells, Electrolyzers

Shape : Rectangular Flat Sheet/Cloth

Material : Durion LMW Cloth with Platinum (Pt) Catalyst

Hardness : Flexible, Nonrigid

Fumasep FAA-3-20

Chemical Composition : Fluorinated polymer backbone with quaternary ammonium functional groups

Density : 0.95 Gram per cubic centimeter(g/cm3)

Application : Fuel Cells, Electrolyzers, Redox Flow Batteries, Electrodialysis

Shape : Flat Sheet / Membrane

Material : Polymer Blend (Anion Exchange Membrane)

|

ULTRANANOTECH PRIVATE LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry