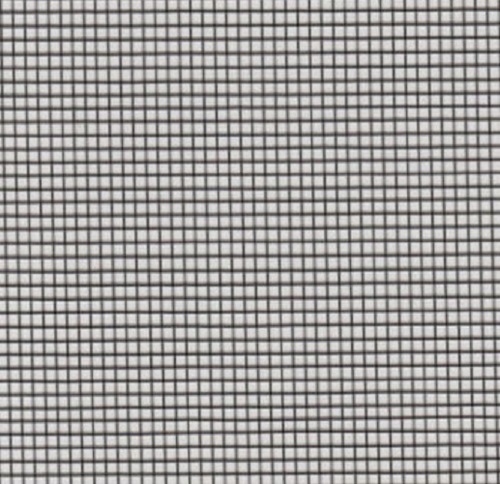

Polypropylene Turbulence Promoter Mesh

Polypropylene Turbulence Promoter Mesh Specification

- Material

- Polypropylene

- Application

- Turbulence promoter for filter cartridges, cooling towers, water treatment systems, and chemical processing applications

- Chemical Composition

- Polypropylene homopolymer (C3H6)n

- Shape

- Mesh/Grid

- Hardness

- Shore D 78

- Density

- 0.90 Gram per cubic centimeter(g/cm3)

- Thickness

- 0.5 mm to 3 mm (varies by requirement)

- Temperature Resistance

- Up to 90°C continuous

- Recyclability

- 100% recyclable

- Porosity

- High, for optimum fluid flow

- Manufacturing Process

- Extrusion and stretching

- Flammability Rating

- HB (UL 94 Standard)

- UV Resistance

- Moderate (can be enhanced as per requirement)

- Toxicity

- Non-toxic, food-grade

- Corrosion Resistance

- Excellent, resistant to most acids, alkalis, and organic solvents

- Mesh Type

- Extruded mesh

- Color

- White or Natural

- Width

- Customizable, generally up to 1 meter

- Length

- Customizable, typically in rolls or cut pieces

Polypropylene Turbulence Promoter Mesh Trade Information

- Payment Terms

- Paypal

- Delivery Time

- 15 Days

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

About Polypropylene Turbulence Promoter Mesh

PolypropyleneTurbulence Promoter Mesh

ProductCode: 72500400

This polypropyleneturbulence promoter mesh can be used with acetone, citric acid, and ethylalcohol. This mesh provides good to excellent resistance to non-oxidizing acidsand bases, fats, and most organic solvents.

Widthof the polypropylene turbulence promoter mesh products as follows:

6 x 6 mesh comes with a width of 55"

9 x 9 mesh comes with a width of 54"

23 x 23 mesh comes with a width of 55"

35 x 35 mesh comes with a width of 54

Optimized for Fluid Flow and Performance

Designed with high porosity and a grid structure, this mesh acts as an effective turbulence promoter, ensuring even and accelerated fluid flow within filter cartridges, cooling towers, and water treatment systems. Its tailor-made extrusion process provides the versatility required for various system configurations.

Unmatched Durability and Chemical Resistance

Manufactured from polypropylene homopolymer, the mesh resists corrosion and most acids, alkalis, and solvents, making it ideal for chemical processing and harsh industrial environments. Its Shore D 78 hardness, moderate UV resistance, and continuous temperature rating up to 90C offer robust performance and extended service life.

Safe, Sustainable, and User-Centric Design

This mesh is non-toxic, food-grade, and fully recyclable, aligning with contemporary sustainability standards. Its customizable dimensions and moderate flammability allow easy integration into both commercial and industrial applications, delivering safe and eco-friendly solutions for distributors and end users alike.

FAQ's of Polypropylene Turbulence Promoter Mesh:

Q: How is the Polypropylene Turbulence Promoter Mesh manufactured?

A: The mesh is produced using an extrusion and stretching process that creates its distinct grid structure. This method allows for customizable thickness, width, and length to meet specific application requirements.Q: What applications benefit most from using this mesh?

A: It is ideally suited for use in filter cartridges, cooling towers, water treatment systems, and chemical processing setups. Its high porosity and robust chemical resistance enhance fluid dynamics and operational efficiency in these applications.Q: When should I choose this mesh over other turbulence promoters?

A: Select this mesh when you require a non-toxic, food-grade, highly porous, and corrosion-resistant solution capable of withstanding continuous temperatures up to 90C. Its adaptability makes it ideal for situations demanding material durability and flow optimization.Q: Where can I source this mesh if I am in the United States?

A: The mesh is available through a network of distributors, manufacturers, suppliers, retailers, and traders across the United States. Customization options are typically offered by these providers depending on your project's specifications.Q: What is the process for customizing the mesh dimensions?

A: Customization is straightforward. Providers collaborate with clients to determine required thickness (0.5-3mm), width (up to 1 meter), and length (in rolls or cut pieces) to ensure seamless integration into your system.Q: How does the mesh promote fluid flow within filtration systems?

A: Its high-porosity, grid design promotes rapid and even turbulence, preventing channeling and enhancing filtration efficiency. This results in better contaminant removal and longer filter lifespan.Q: What are the environmental and safety benefits of using this polypropylene mesh?

A: The mesh is 100% recyclable, non-toxic, and food-grade, making it safe for a wide range of applications. It features a moderate flammability rating (HB under UL 94), and its chemical resistance reduces the risk of hazardous reactions and material degradation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Fuel Cell Membranes Category

Pention-AEM-72-05-15 Crosslinking

Material : AEM (Ethylene Acrylate Rubber)

Chemical Composition : Ethylene acrylate copolymer with crosslinking agent

Density : 1.25 Gram per cubic centimeter(g/cm3)

Application : Crosslinking agent for automotive and industrial rubber parts

Shape : Sheets/strips

Hardness : 72 Shore A

Aquivion E98-15S

Material : Perfluorosulfonic Acid (PFSA) ionomer membrane

Chemical Composition : Equivalent weight 980 g/eq. (E98 series), Sulfonic acidfunctionalized tetrafluoroethylenebased fluoropolymer

Density : 2.1 Gram per cubic centimeter(g/cm3)

Application : Fuel cells, electrolyzers, electrochemical applications

Shape : Membrane sheet

Hardness : Not specified (flexible solid film)

Fumapem AM-40 - PBI Copolymer

Material : PBI Copolymer (Polybenzimidazole Copolymer)

Chemical Composition : PBI Copolymer, Modified Aromatic Polymer with Ionic Groups

Density : 1.40 Gram per cubic centimeter(g/cm3)

Application : PEM fuel cells, Electrolyzers, Hydrogen production, Chemical process industry membranes

Shape : Membrane/Film

Hardness : Shore D 4045

Xion BPM-Aquivion-870-Durion-LMW-30 m

Material : Aquivion Ionomer Membrane

Chemical Composition : Perfluorosulfonic acid (PFSA) ionomer

Density : 2.1 Gram per cubic centimeter(g/cm3)

Application : Electrochemical processes, Water electrolyzers, Fuel Cells, Hydrogen production

Shape : Bipolar Plate Membrane Sheet

Hardness : Medium

|

ULTRANANOTECH PRIVATE LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry