MEA PEM Dyneon 725 05I m 0.5mgPt Cloth

MEA PEM Dyneon 725 05I m 0.5mgPt Cloth Specification

- Material

- PEM (Proton Exchange Membrane) with Dyneon 725 and platinum catalyst on cloth backing

- Application

- Proton Exchange Membrane Fuel Cells (PEMFC), Hydrogen Electrolyzers, Electrochemical cells

- Chemical Composition

- Perfluorosulfonic acid membrane (Dyneon 725) with platinum catalyst (0.5 mg/cm) supported on carbon cloth

- Shape

- Sheet/Cloth

- Hardness

- Soft, flexible membrane

- Density

- 2.0 Gram per cubic centimeter(g/cm3)

- Operating Temperature

- Up to 80°C

- Thickness

- 5 microns (0.005 mm)

- Electrode Type

- Membrane Electrode Assembly (MEA)

- Membrane Area

- Customizable, based on requirement

- Storage Conditions

- Dry/cool environment, avoid direct UV exposure

- Reinforcement

- Carbon cloth support

- Surface Finish

- Smooth, micro-porous

- Catalyst Loading

- 0.5 mg Pt/cm²

- Ionic Conductivity

- >0.1 S/cm (typical for Dyneon 725 membranes)

- Gas Permeability

- Low gas crossover

MEA PEM Dyneon 725 05I m 0.5mgPt Cloth Trade Information

- Payment Terms

- Paypal

- Delivery Time

- 15 Days

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

About MEA PEM Dyneon 725 05I m 0.5mgPt Cloth

MEA PEM Dyneon-72505 0.5mg Pt Cloth

Product Code: 74810001

XICAT Membrane Electrode Assemblies (MEA) are highlydurable and they provide ultra-high performance assemblies for use inelectrochemical applications due to the use of ultra-thin composite membranes.

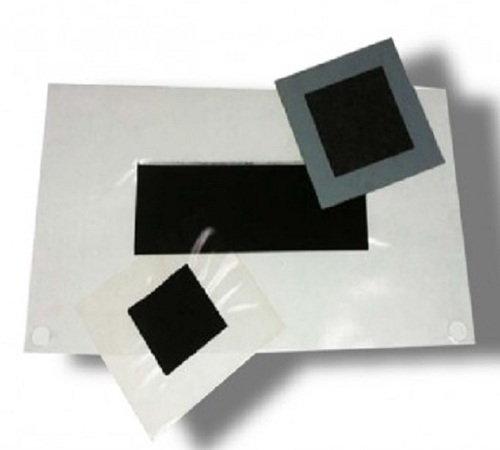

MEA PEM-Dyneon-725-05m-0.5mgPt-Cloth product iscomprised of the following sub-components: 5 micrometers thick PEM-Dyneon (EW725) composite membrane and carbon cloth based gas diffusion electrodes with0.5 mg/cm2 loading of 60% Pt/C catalysts both for anode andanode.

Xergy has the largest selection of composite protonexchange membranes (C-PEM) and proton exchange ionomers (PEI) and compositeanion exchange membranes (C-AEM) and anion exchange ionomers (AEI) to selectfrom for the XICAT MEA design. C-PEMs/PEIs for the XICAT MEAs are availablefrom Dyneon, Aquivion, and Nafion perfluorosulfonic acid (PFSA)ionomers. C-AEMs/AEIs are available from Durion and Pentionionomers. The standard MEA is a 5-layer construction with a membrane sandwichedbetween a gas diffusion electrode and catalyst layer. A second MEA structure isa 3-layer construction known as a catalyst coated membrane (CCM), in which thecatalyst is applied directly to the membrane and there is no gas diffusionlayer.

Advanced PEM Technology for Efficient Energy

Engineered with Dyneon 725 perfluorosulfonic acid membrane and platinum catalyst, this MEA delivers superior ionic conductivity and minimal gas crossover. Its carbon cloth reinforcement ensures durability while maintaining flexibility, making it ideal for next-generation PEM fuel cells and electrolyzer systems requiring consistent performance and reliable operation.

Customizable Membrane Area for Versatile Applications

Membrane area can be tailored according to user requirements, making it suitable for both research and large-scale systems. Whether for hydrogen generation, fuel cell stacks, or custom electrochemical setups, this product provides adaptable solutions to meet diverse energy and research demands with precision.

FAQ's of MEA PEM Dyneon 725 05I14m 0.5mgPt Cloth:

Q: How can the membrane area of the MEA PEM Dyneon 725 cloth be customized for specific needs?

A: The membrane area is customizable based on user specifications. Customers can specify desired dimensions when ordering to suit unique experimental setups or commercial fuel cell stack requirements, ensuring optimal integration and performance.Q: What are the key benefits of using the Dyneon 725 05m 0.5mgPt cloth in PEM fuel cells and electrolyzers?

A: This MEA offers excellent ionic conductivity (>0.1 S/cm), low gas permeability, and robust mechanical reinforcement from carbon cloth, providing enhanced efficiency, stability, and reduced gas crossover for high-performance PEM fuel cells and hydrogen electrolyzers.Q: When and how should the MEA PEM Dyneon 725 membrane be stored for longevity?

A: To preserve membrane integrity and performance, store the MEA in a dry, cool environment and avoid direct UV exposure. Proper storage ensures its catalytic and conductive properties remain optimal over time.Q: Where is the MEA PEM Dyneon 725 0.5mgPt cloth available for distribution and purchase in India?

A: The MEA PEM Dyneon 725 05m 0.5mgPt cloth is available through distributors, manufacturers, suppliers, traders, and retailers across India, catering to academic, industrial, and research sectors.Q: What is the process of integrating the MEA PEM Dyneon 725 cloth into a fuel cell or electrolyzer system?

A: Integration involves placing the MEA between flow plates and gaskets within the system structure. Its flexible, sheet-like nature and customizable sizing enable straightforward assembly compatible with standard PEMFC and electrolyzer configurations.Q: What is the typical usage of the MEA PEM Dyneon 725 cloth and what applications does it support?

A: It is primarily used for Proton Exchange Membrane Fuel Cells (PEMFC), hydrogen electrolyzers, and various electrochemical cells. Its properties suit both small-scale research and commercial energy systems requiring reliable and efficient proton conduction.Q: How does the carbon cloth reinforcement benefit the overall mechanical properties of the membrane?

A: Carbon cloth serves as a robust backing, enhancing flexibility and mechanical strength. This reinforcement ensures better handling during assembly, increased durability under operational stresses, and extended service life of the membrane within energy systems.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Fuel Cell Membranes Category

Porex PM21M

Shape : Sheet

Application : Filtration, Venting, Wicking, Fluid Control

Material : Microporous Polyethylene

Chemical Composition : High Density Polyethylene (HDPE)

Density : 0.6 Gram per cubic centimeter(g/cm3)

Hardness : Shore D 4560

Fumapem AM-40 - PBI Copolymer

Shape : Membrane/Film

Application : PEM fuel cells, Electrolyzers, Hydrogen production, Chemical process industry membranes

Material : PBI Copolymer (Polybenzimidazole Copolymer)

Chemical Composition : PBI Copolymer, Modified Aromatic Polymer with Ionic Groups

Density : 1.40 Gram per cubic centimeter(g/cm3)

Hardness : Shore D 4045

Fumasep FAA-3-20

Shape : Flat Sheet / Membrane

Application : Fuel Cells, Electrolyzers, Redox Flow Batteries, Electrodialysis

Material : Polymer Blend (Anion Exchange Membrane)

Chemical Composition : Fluorinated polymer backbone with quaternary ammonium functional groups

Density : 0.95 Gram per cubic centimeter(g/cm3)

Xion PEM-Aquivion-830-20

Shape : Flat Sheet Membrane

Application : Polymer Electrolyte Membrane for Fuel Cells and Electrolyzers

Material : Perfluorosulfonic Acid (PFSA) ionomer membrane

Chemical Composition : Equivalent to Aquivion E830; Perfluorinated copolymer with sulfonic acid functional groups

Density : 2.1 Gram per cubic centimeter(g/cm3)

|

ULTRANANOTECH PRIVATE LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry