Porex PM21M

Porex PM21M Specification

- Material

- Microporous Polyethylene

- Application

- Filtration, Venting, Wicking, Fluid Control

- Chemical Composition

- High Density Polyethylene (HDPE)

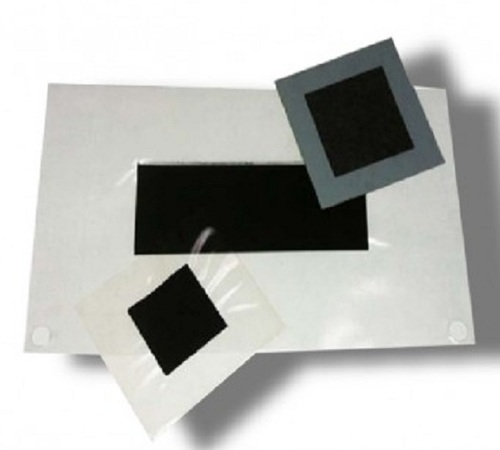

- Shape

- Sheet

- Hardness

- Shore D 4560

- Density

- 0.6 Gram per cubic centimeter(g/cm3)

- Thickness

- 1 mm

- Pore Size

- 21 micron (nominal)

- Tensile Strength

- 46 MPa

- Porosity

- 3550%

- Water Absorption

- <1% of weight

- Maximum Operating Temperature

- 80C

- Air Permeability

- 150250 l/h/dm at 1 kPa

- Color

- White

Porex PM21M Trade Information

- Payment Terms

- Paypal

- Delivery Time

- 15 Days

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

About Porex PM21M

Brand: PorexCorporation

Product Code: 150817

Porex is amicro-expanded PTFE product that allows gasses to permeate but has a highbarrier for liquid water. Porex can be used in instances where gas permeationis desired, but liquid is not. This material is perfect for vents, gas/liquidseparation membranes, etc. It is not a Proton Exchange Membrane (PEM) materiallike Nafion and is a non-conductive insulator.

The evolution of thebattery to more energy-dense, rapid-charging systems has brought new uses forporous materials such as membranes, separators, catalytic support, and fuelcell membranes. Battery systems can still expand with heat and contract duringnormal use, so numerous venting configurations are offered to equalize batterypressure and to allow heat flow. Advanced electrode materials, diffusionbarriers, and electrolyte carriers are also available to optimize performancein a variety of battery and fuel cell configurations.

Porex Microporous PTFE Breathable MembranesOffer:

High water intrusion pressure resistance

High temperature use

High tensile strength

IP 65, 66, 67 & 68 ratings

UL-94 V-0 rating @ 0.1 mm, 5VA rated @ 0.75 mm

UL 746C rated

Superior Microporous Design

Porex PM21M utilizes advanced microporous technology in high-density polyethylene, resulting in consistently controlled pore structure (21 micron nominal) and high porosity. These characteristics enable reliable filtration, venting, and wicking actions-vital for industries requiring precise fluid control. Its controlled permeability optimizes both air and fluid passage, making it suitable for a spectrum of technical applications.

Durability and Safety Assured

Engineered to endure, Porex PM21M maintains mechanical integrity under stress, featuring a tensile strength of 4-6 MPa and a Shore D hardness of 45-60. Its ability to operate at temperatures up to 80C and negligible water absorption ensures sustainable performance in moisture-prone and chemically challenging environments.

Versatile Applications Across Industries

Porex PM21M is widely adopted for filtration, venting, wicking, and fluid management in sectors ranging from medical devices to aerospace. Its white sheet form facilitates easy customization and integration into end products. Distribution, manufacturing, and supplier networks across the United States make sourcing convenient for various businesses and research sectors.

FAQ's of Porex PM21M:

Q: How is Porex PM21M typically used in industrial applications?

A: Porex PM21M is widely utilized for filtration, venting, wicking, and fluid control tasks. Its precise pore size and high porosity enable effective separation of particles, controlled airflow, and consistent fluid movement in devices such as filters, aerators, and sensors.Q: What benefits does the 21-micron nominal pore size provide?

A: The 21-micron nominal pore size delivers controlled filtration and venting performance, ensuring that particles above this size are efficiently blocked while permitting sufficient airflow or fluid movement. This is crucial for applications requiring both purity and breathability.Q: Where can I source Porex PM21M in the United States?

A: Porex PM21M is available through a network of authorized distributors, manufacturers, suppliers, traders, and retailers across the United States. Contacting Porex or verified partners directly ensures timely procurement and product support.Q: What process is used for manufacturing Porex PM21M sheets?

A: Porex PM21M sheets are produced by sintering high-density polyethylene particles, creating a uniform microporous structure. This process guarantees consistent pore distribution, stable dimensional properties, and high mechanical strength of the final product.Q: When is it advantageous to use Porex PM21M over other filtration materials?

A: It is particularly beneficial to use Porex PM21M when demanding applications require a combination of chemical resistance, low water absorption, mechanical durability, and precise pore size, such as in medical, laboratory, and ventilated packaging sectors.Q: What is the water absorption characteristic of Porex PM21M, and why is it important?

A: Porex PM21M has a water absorption rate of less than 1% of its weight. This attribute is essential in applications where material stability and performance are critical even in high-moisture or humid environments.Q: How does air permeability impact the performance of Porex PM21M?

A: With an air permeability of 150-250 l/h/dm2 at 1 kPa, Porex PM21M ensures efficient airflow, which is crucial for venting and wicking applications. This property enhances its effectiveness in products that require reliable air or gas flow while maintaining filtration quality.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Fuel Cell Membranes Category

MEA AEM Durion LMW 30I m 0.5mgPt Cloth

Shape : Rectangular Flat Sheet/Cloth

Application : Electrochemical Devices, Fuel Cells, Electrolyzers

Material : Durion LMW Cloth with Platinum (Pt) Catalyst

Chemical Composition : Low Molecular Weight Durion, Supported Platinum (0.5 mg/cm)

Hardness : Flexible, Nonrigid

Density : 1.8 Gram per cubic centimeter(g/cm3)

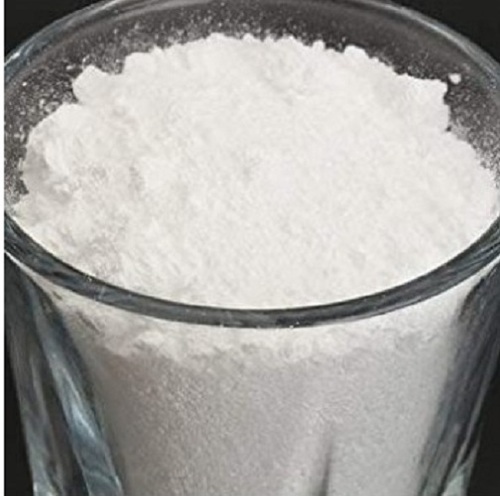

Aquivion PW79S

Shape : Granular Powder

Application : Proton Exchange Membranes, Fuel Cells, Electrolysis, Chloralkali Applications

Material : Perfluorosulfonic Acid (PFSA) Ionomer

Chemical Composition : Equivalent Weight (EW) 790 g/eq, Sulfonic Acid Groups

Hardness : Not Applicable (Powder form)

Density : 2.0 Gram per cubic centimeter(g/cm3)

Xion BPM-Aquivion-870-Durion-LMW-30 m

Shape : Bipolar Plate Membrane Sheet

Application : Electrochemical processes, Water electrolyzers, Fuel Cells, Hydrogen production

Material : Aquivion Ionomer Membrane

Chemical Composition : Perfluorosulfonic acid (PFSA) ionomer

Hardness : Medium

Density : 2.1 Gram per cubic centimeter(g/cm3)

Aquivion E98-15S

Shape : Membrane sheet

Application : Fuel cells, electrolyzers, electrochemical applications

Material : Perfluorosulfonic Acid (PFSA) ionomer membrane

Chemical Composition : Equivalent weight 980 g/eq. (E98 series), Sulfonic acidfunctionalized tetrafluoroethylenebased fluoropolymer

Hardness : Not specified (flexible solid film)

Density : 2.1 Gram per cubic centimeter(g/cm3)

|

ULTRANANOTECH PRIVATE LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry