Carbon Fumapem AM-40 - PBI Copolymer

Carbon Fumapem AM-40 - PBI Copolymer Specification

- Material

- PBI Copolymer Membrane

- Application

- Electrochemical Devices such as Fuel Cells, Electrolyzers, and Redox Flow Batteries

- Chemical Composition

- Polybenzimidazole (PBI) Copolymer

- Shape

- Membrane / Flat Sheet

- Hardness

- 74 Shore A

- Density

- 1.35 Gram per cubic centimeter(g/cm3)

- Storage Conditions

- Store at room temperature, dry and dark place

- Tensile Strength

- >22 MPa

- Operating Temperature Range

- Up to 180C

- Proton Conductivity

- High (optimized for proton exchange)

- Water Uptake

- 55% (in acid solution)

- Customization

- Available in other thicknesses upon request

- Thickness

- 40 microns

- Color

- Light Yellow

- Dimensional Stability

- High, minimal swelling

- Elongation at Break

- >15%

- Shelf Life

- 12 months (under specified storage conditions)

- Ionic Conductivity

- 0.10 S/cm (in acid solution)

Carbon Fumapem AM-40 - PBI Copolymer Trade Information

- Payment Terms

- Paypal

- Delivery Time

- 15 Days

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

About Carbon Fumapem AM-40 - PBI Copolymer

Brand:FuMA-Tech

Product Code:5041632

FumapemAM-40 is a non-reinforcedPolybenzimidazole Copolymermembranedesigned for use in High-Temperature Proton Electrolyte Fuel Cells (HT-PEMFC).The polymer backbone for this HT-PEMFC membrane is categorized as a hydrocarbonpolymer material.

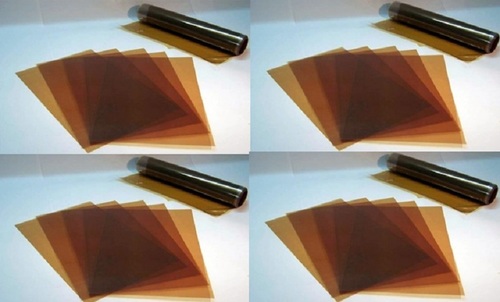

FumapemAM-40 membrane comes in either a 10cm x 10cm or 20cm x 30cm size sheet. Themembrane is the brown foil delivered in dry form.

Fumatechmembranes are highly sensitive to differences in humidity and moisture content.Therefore the membranes can vary +/- 0.5cm from the original cut sizes. Alsodue to this sensitivity the manufacturer expects wrinkles to form, howeversoaking the membranes in deionized water will return the membranes to the fullsize planar state according to the manufacturer.

FumapemAM-40 Features:

Applications:High-Temperature PEM Fuel Cell (HT-PEMFC).

Thickness: 40 micrometers (1.57 mil)

Sizes: 10cm x 10cm, 20cm x 30cm

Handling:

Keep membrane package closed / sealed when unused. Store,handle and process the membrane in a clean and dust-free area. Use only new andsharp knives or blades, when cutting the membrane. Always wear protectivegloves when handling the membrane. Handle with care, be sure not to puncture,crease or scratch the membrane, otherwise leaks will occur. All surfaces incontact with the membrane during handling, inspection, storage and mountingmust be smooth and free of sharp projections.

Doping with Phosphoric AcidRecommendation:

Put the membrane sample in 85 wt % H3PO4 at temperaturesbetween 90C and 160C for at least 1 hour. Membranes must be covered byphosphoric acid. Membranes will expand when subject to doping process.

If you have any concerns about storage, chemicalstability, pre-treatment or before proceeding, please feel free to contact usfor further information.

Long Term Storage:

The membrane can be stored dry for anunlimited amount of time. However, the membrane has to be conditioned (washedand rinsed) prior to use.

Advanced Material for Electrochemical Applications

Fumapem AM-40 leverages the robust properties of PBI copolymer to provide a durable and reliable solution for modern electrochemical devices, including fuel cells, electrolyzers, and redox flow batteries. This membrane excels in challenging environments, thanks to its remarkable chemical, tensile, and dimensional stability, even at high operating temperatures.

Optimized Performance and Customization

Designed to deliver high proton conductivity and minimal swelling, Fumapem AM-40 ensures superior efficiency and consistency during device operation. The membrane can be tailored in thickness upon request, making it adaptable to a broad range of industrial specifications and research requirements.

FAQ's of Fumapem AM-40 - PBI Copolymer:

Q: How should Fumapem AM-40 be stored to ensure its maximum shelf life?

A: Fumapem AM-40 should be stored at room temperature in a dry and dark location. Following these conditions helps maintain its quality and guarantees a shelf life of up to 12 months.Q: What are the primary applications of the Fumapem AM-40 membrane?

A: Fumapem AM-40 is primarily designed for use in electrochemical devices, such as fuel cells, electrolyzers, and redox flow batteries, where high proton conductivity and chemical stability are required.Q: When is it beneficial to choose Fumapem AM-40 for a project?

A: Fumapem AM-40 is ideal when projects demand high thermal and chemical stability, especially under acidic, oxidative, or high-temperature conditions (up to 180C), ensuring long-term durability and performance.Q: Where can customers purchase Fumapem AM-40 membranes in the United States?

A: Fumapem AM-40 is available through authorized distributors, manufacturers, retailers, suppliers, and traders across the United States. For specific ordering information, it is best to contact an official supplier directly.Q: What makes Fumapem AM-40 stand out in terms of durability and efficiency?

A: The membrane's construction from PBI copolymer imparts exceptional toughness, evidenced by its >22 MPa tensile strength and >15% elongation at break. Its high dimensional stability and resistance to acidic and oxidative environments ensure reliable and long-lasting device operation.Q: How does customization work for Fumapem AM-40 membranes?

A: Customers can request Fumapem AM-40 in different thicknesses to match their technical requirements. This adaptability allows for seamless integration into various device architectures and research projects.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Fuel Cell Membranes Category

Porex PM21M

Shape : Sheet

Application : Filtration, Venting, Wicking, Fluid Control

Material : Microporous Polyethylene

Chemical Composition : High Density Polyethylene (HDPE)

Density : 0.6 Gram per cubic centimeter(g/cm3)

Hardness : Shore D 4560

MEA PEM Dyneon 725 05I m 0.5mgPt Cloth

Shape : Sheet/Cloth

Application : Proton Exchange Membrane Fuel Cells (PEMFC), Hydrogen Electrolyzers, Electrochemical cells

Material : PEM (Proton Exchange Membrane) with Dyneon 725 and platinum catalyst on cloth backing

Chemical Composition : Perfluorosulfonic acid membrane (Dyneon 725) with platinum catalyst (0.5 mg/cm) supported on carbon cloth

Density : 2.0 Gram per cubic centimeter(g/cm3)

Hardness : Soft, flexible membrane

Aquivion P98-SO2F

Shape : Granular or Pellet

Application : Used in the production of ionexchange membranes, fuel cells, and specialty chemical processes

Material : Perfluorosulfonic Acid (PFSA) Polymer

Chemical Composition : SO2F (Sulfonyl Fluoride) end groups; Perfluorinated backbone

Density : 2.1 Gram per cubic centimeter(g/cm3)

Fumasep FAS-PET-75 Anion Exchange Membrane (AEM)

Shape : Flat sheet membrane

Application : Electrodialysis, fuel cells, water electrolyzers, and electrochemical devices

Material : Perfluorinated polymer with PET support

Chemical Composition : Functionalised aromatic polymer with quaternary ammonium groups on PET support

Density : 1.05 Gram per cubic centimeter(g/cm3)

Hardness : Flexible

|

ULTRANANOTECH PRIVATE LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry