Protium 50

Protium 50 Specification

- Hardness

- 45-55 HRC

- Strength

- High tensile strength

- Purity

- 99% - 100% approx.

- Product Type

- Wear Resistant Plate

- Material

- Alloyed Steel (Proprietary blend)

- Alloy

- Yes

- Shape

- Rectangular Plate

- Moisture

- <0.1% by weight

- Chemical Composition

- Fe, C, Si, Mn, S, P, Cr, Ni, Mo

- Application

- Mining, Cement, Power, Steel, Recycling Industries

- Dimension (L*W*H)

- 400mm x 400mm x 12mm

- Color

- Grey

- Operating Temperature

- Up to 400°C

- Packaging Type

- Wooden Pallet

- Weight (Per Plate)

- Approximately 130 kg

- Edge Type

- Smooth/Customizable

- Abrasion Resistance

- Superior (suitable for heavy impact and wear applications)

- Surface Finish

- Smooth with anti-corrosive coating

- Thickness Tolerance

- ±0.5 mm

- Processing Capability

- Can be cut, drilled, and welded

Protium 50 Trade Information

- Payment Terms

- Paypal

- Delivery Time

- 15 Days

- Main Export Market(s)

- Australia, North America, Eastern Europe, Middle East, Central America, South America, Asia

- Main Domestic Market

- All India

About Protium 50

Protium-50

ProductCode: 1021961

The Protium-50 is an advanced hydrogen PEM fuel cell thatis designed for tomorrow's unmanned vehicles. The Protium Series is theflagship suite of fuel cell systems and the culmination of more than a decadeof cutting edge R&D. Every Protium fuel cell is made of the best qualitymembrane electrode assemblies to ensure the highest power output in thesmallest form factor.

Includes:

- Open cathode, aircooled, graphite bipolar plates

- 20-cells graphite plate fuel cell stack

- Electronic controller

- Purge solenoid valve, gas connectors andgas tubing

- Cooling fan with fan casing

- Stack power output and load connectors

Technical Specifications:

- Rated/Gross Power: 50/60W

- Rated/Gross Current: 4.2/5A

- Voltage Output: 12-18V DC

- Start-up Time: 5s

- Operating Ambient Temp.: (0,40]°C

- Operating Altitude: 1500m AGL

- System Weight: 480g

- Dimensions: 130 x 76 x 85 mm

Fuel Supply:

- Hydrogen Gas: Dry, 99.999% purity

- Delivery Pressure: 0.3-0.35 barg (4-5psig)

- Fuel Consumption: 0.6L/min

- Gas Tubing: Silicon, ID 4mm

- Purge Control: Automated periodic purgevia solenoid valve

Electronic Controller:

- Processor Board: Mini V1.0

- PCBA Dimension: 70 x 60 x 30 mm

- PCBA Weight: 56g

- Output Connector (Stack): Banana testconnector receptacle and plug

- Output Connector (Load): Terminal block,20A,12-22AWG

- External Power Requirement: 5V, 0.5A

Suggested Hybrid Lipo Battery

This fuel cell system requires the use of 3S LiPo battery(>50C discharge rated). The ultra-lightweight feature of the Protium-50 fuelcell system comes from the elimination of bulky and heavy external humidifiersneeded for PEM fuel cell technology. An automated fuel cell stack conditioningprotocol maintains the hydration of the membrane. During the stack conditioningevent, fuel cell system briefly gets disconnected from the load (approximately100 milliseconds). A small LiPo battery needs to be used to provide electricalenergy to the load during the stack conditioning event.

Operation of the Fuel Cell - Hybrid LiPoBattery For UAVs

The ultra-lightweight Protium-50 fuel cellsystem works in tandem with the Hybrid LiPo battery. During the startup of thefuel cell, the Hybrid LiPo battery provides the electrical energy to initializeall the electronics. For the power demand up to 50 W, the electrical energy issolely supplied by the fuel cell stack. For events such as take off andemergencies that demand more than 50 W for short durations, LiPo batteryprovides all the electrical energy needed. For the most efficient use of thistandem power architecture, it is suggested that fuel cell stack to be used forcruising part of the flight and Hybrid LiPo battery to be used during take-offand short duration emergencies.

We have different configuration products for the same. Please you can directly call us to Dr. Arup: 8452810712.

Engineered for Heavy-Duty Industry

Protium 50 is designed specifically for sectors where robust performance and longevity are paramount, such as mining, cement, and recycling. Its superior abrasion resistance and customizable edge options ensure that it meets the toughest operational demands, while its anti-corrosive coating prolongs service life, even in challenging environments.

Precision Manufacturing for Reliable Results

Every Protium 50 plate boasts an exacting thickness tolerance of 0.5 mm, ensuring consistent quality across batches. Its proprietary alloy composition is optimized for high tensile strength and hardness, offering significant advantages in sustaining mechanical stress and resisting surface wear compared to standard alternatives.

FAQ's of Protium 50:

Q: How can Protium 50 plates be processed for specific applications?

A: Protium 50 plates are engineered to be highly versatile in processing. They can be cut, drilled, and welded according to your application requirements. Custom edge options are also available to ensure seamless integration into your existing setups.Q: What industries benefit most from using Protium 50 alloyed steel plates?

A: Industries that experience heavy impact and wear, such as mining, cement, power generation, steel manufacturing, and recycling, gain significant advantages from Protium 50's high abrasion resistance, strength, and longevity.Q: When is it advisable to choose Protium 50 over standard steel plates?

A: Protium 50 should be chosen when applications demand high abrasion resistance, hardness (45-55 HRC), and reliable performance at temperatures up to 400C. This makes it suitable for environments involving heavy loads or rapid material movement.Q: Where are Protium 50 plates manufactured and distributed?

A: Protium 50 plates are manufactured, distributed, and supplied throughout the United States by reputable manufacturers, distributors, suppliers, retailers, and traders specializing in high-performance alloyed steel products.Q: What is the typical benefit of using Protium 50 plates?

A: The main benefit of using Protium 50 is its superior wear and impact resistance, ensuring a longer service life for equipment. Its high purity alloy composition and anti-corrosive coating further contribute to efficiency and reduced maintenance costs.Q: How does the anti-corrosive coating improve the product's performance?

A: The smooth, anti-corrosive coating on Protium 50 plates protects against rust and chemical deterioration, even in harsh environments. This feature extends the operational lifespan of the steel plates and reduces downtime related to maintenance.Q: What process ensures consistent thickness and quality in Protium 50 plates?

A: Protium 50 is manufactured under strict quality controls with a thickness tolerance of 0.5 mm, ensuring dimensional consistency for precise assembly and dependable mechanical properties across every plate delivered.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Fuel Cell Stacks Category

GreenHub 2 a 5000

Product Type : Other, Cathode

Dimension (L*W*H) : 150 mm x 125 mm x 57 mm

Shape : Other, Rectangular Block

Application : Other, Industrial, Electrical

Material : Copper

Color : Silver Grey

GreenBox 2 - 100

Product Type : Other, Encased Power Module

Dimension (L*W*H) : 120 mm x 85 mm x 35 mm

Shape : Other, Rectangular

Application : Other, Industrial automation, electric panels

Material : Advanced Metal Compound

Color : Green

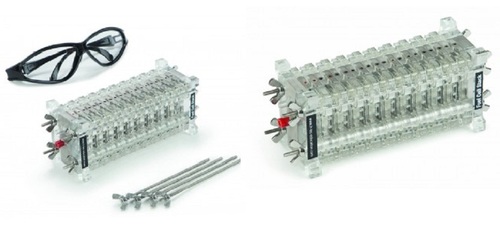

Flex-Stak Electrochemical Cell

Product Type : Other, Electrochemical Cell Stack

Dimension (L*W*H) : Modular Design; Approx. 80 x 80 x 150 mm (per standard stack, customizable)

Shape : Other, Rectangular Stack Modules

Application : Other, Fuel cell research, water electrolysis, electrochemical testing, educational demonstration

Material : Polycarbonate plates, Platinum electrodes, Carbon felt, Membrane (Nafion/PEM)

Color : Transparent/White and Blue (as seen in Image)

Fuel Cell Stack 10

Product Type : Other, Proton Exchange Membrane (PEM) Fuel Cell Stack

Dimension (L*W*H) : Approx. 200mm x 100mm x 90mm

Shape : Other, Rectangular stack

Application : Other, Education, Research, Demonstration, Portable Power

Material : Graphite, Platinum, Composite Housing

Color : Metallic Silver & Black modules

|

ULTRANANOTECH PRIVATE LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry