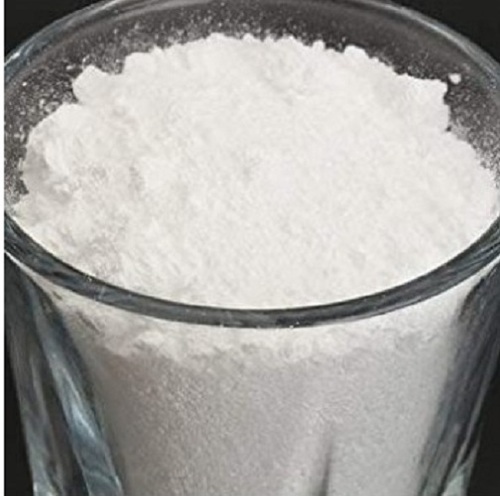

Nafion R-1000 Precursor Beads

Nafion R-1000 Precursor Beads Specification

- Material

- Perfluorosulfonic acid/PTFE copolymer precursor

- Application

- Used as a precursor for manufacturing Nafion membranes and films via extrusion or casting; also for research and industrial ion-exchange processes

- Chemical Composition

- Polytetrafluoroethylene (PTFE) backbone with perfluoro-sulfonyl fluoride side chains

- Shape

- Spherical beads

- Hardness

- High mechanical strength, typical for PTFE polymers

- Density

- 2.1 Gram per cubic centimeter(g/cm3)

- Melting Point

- About 260°C

- Purity

- High chemical purity for membrane production

- Odor

- Odorless

- Thermal Stability

- Excellent, suitable for high-temperature processing

- Particle Size

- Typically ranges from 500 to 1200 microns

- Ionic Form

- Precursor (sulfonyl fluoride), not ion-exchanged

- Color

- Off-white to translucent

- Moisture Absorption

- Very low

- Shelf Life

- Stable under proper storage conditions

- Packaging

- Sealed bottles or bags to prevent contamination

Nafion R-1000 Precursor Beads Trade Information

- Payment Terms

- Paypal

- Delivery Time

- 15 Days

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

About Nafion R-1000 Precursor Beads

Brand: Chemours

Product Code: 72500302

Chemours (formerlyDuPont) Resins are perfluorinated polymers used to manufacture ion-exchangemembranes, catalysts, and related materials. It is a copolymer of tetrafluoroethyleneand perfluoro-3,6-dioxa-4-methyl-7-octenesulfonyl fluoride. This thermoplasticpolymer must be hydrolyzed to convert it to a form suitable for use inion-exchange applications.

Nafion R-1000 Technical Specifications:

Bead size: 7-9 mesh(3mm x 4mm)

Bulk density (g/cc): 1.25

Ion exchange capacity (meq/g)*: 1.0 (after hydrolysis)

Exceptional Chemical Purity for Advanced Applications

Nafion R-1000 Precursor Beads boast high chemical purity, which is critical for producing reliable Nafion membranes and films. Their purity facilitates accurate research outcomes and enhances industrial ion-exchange processes, allowing users to achieve consistent results in demanding environments. Each bead is manufactured to strict standards and packaged securely to preserve quality.

Superior Mechanical Strength and Thermal Stability

These precursor beads exhibit high mechanical strength typical of PTFE-based polymers, and maintain their integrity at processing temperatures up to 260C. Their excellent thermal stability makes them an optimal choice for extrusion and casting operations, ensuring durability and reliable performance in harsh conditions.

Versatile Usage Across Research and Industry

Engineered for both laboratory research and large-scale production, Nafion R-1000 Precursor Beads serve as essential materials for manufacturing Nafion membranes and films. Their low moisture absorption and stable shelf life support prolonged storage and versatile applications in ion-exchange systems. Spherical shape and controlled sizing support precise process control.

FAQ's of Nafion R-1000 Precursor Beads:

Q: How are Nafion R-1000 Precursor Beads typically used in membrane production?

A: These beads are primarily used as a precursor for manufacturing Nafion membranes and films, typically through extrusion or casting processes. Their chemical stability and controlled particle size help ensure uniformity and reliability during production.Q: What benefits do precursor beads in sulfonyl fluoride form offer compared to ion-exchanged forms?

A: The sulfonyl fluoride precursor form allows customization of the final ionic properties during membrane fabrication, offering flexibility for specific research or industrial ion-exchange applications. It also contributes to the high chemical purity essential for membrane integrity and function.Q: When should Nafion R-1000 Precursor Beads be processed to achieve optimal quality membranes?

A: Processing is typically performed when beads are freshly obtained and stored under recommended conditions, as their stable shelf life and low moisture absorption help preserve chemical properties. High-temperature operations ( 260C) are recommended for best results.Q: Where in the United States can Nafion R-1000 Precursor Beads be purchased?

A: Nafion R-1000 Precursor Beads are available through various distributors, manufacturers, suppliers, retailers, and traders across the United States. Buyers should seek reputable sources to ensure product authenticity and proper packaging.Q: What process is involved in converting these precursor beads into functional membranes?

A: After extrusion or casting of the beads into films or membranes, a chemical conversion step exchanges the sulfonyl fluoride groups for desired ionic forms, enabling ion-exchange capabilities. These steps result in robust, functional Nafion membranes.Q: How does the packaging help maintain the quality of Nafion R-1000 Beads?

A: Packaged in sealed bottles or bags, the beads are protected from moisture and contamination, which helps retain high purity and stable properties during storage and transportation.Q: What is the advantage of the product's high mechanical hardness and density?

A: Their high mechanical strength and density (2.1 g/cm3) ensure that the beads can endure rigorous processing while maintaining consistent dimensional stability, improving manufacturing yield and membrane durability.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

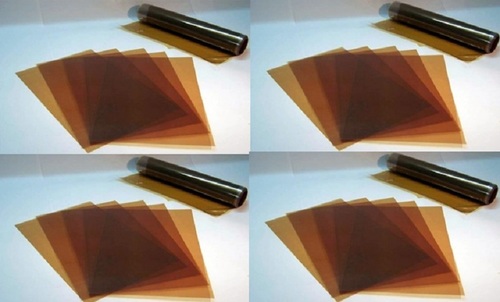

More Products in Fuel Cell Membranes Category

PFSA Membrane Variety Kit

Material : Perfluorosulfonic acid (PFSA) membrane

Chemical Composition : Perfluorosulfonic acid polymer

Application : Electrochemical cell testing, Fuel cells, Electrolysis systems, Research and development

Shape : Sheet

Density : 2.0 Gram per cubic centimeter(g/cm3)

Hardness : Medium

Aquivion PW79S

Material : Perfluorosulfonic Acid (PFSA) Ionomer

Chemical Composition : Equivalent Weight (EW) 790 g/eq, Sulfonic Acid Groups

Application : Proton Exchange Membranes, Fuel Cells, Electrolysis, Chloralkali Applications

Shape : Granular Powder

Density : 2.0 Gram per cubic centimeter(g/cm3)

Hardness : Not Applicable (Powder form)

Aquivion P98-SO2F

Material : Perfluorosulfonic Acid (PFSA) Polymer

Chemical Composition : SO2F (Sulfonyl Fluoride) end groups; Perfluorinated backbone

Application : Used in the production of ionexchange membranes, fuel cells, and specialty chemical processes

Shape : Granular or Pellet

Density : 2.1 Gram per cubic centimeter(g/cm3)

Fumasep FAS-PET-75 Anion Exchange Membrane (AEM)

Material : Perfluorinated polymer with PET support

Chemical Composition : Functionalised aromatic polymer with quaternary ammonium groups on PET support

Application : Electrodialysis, fuel cells, water electrolyzers, and electrochemical devices

Shape : Flat sheet membrane

Density : 1.05 Gram per cubic centimeter(g/cm3)

Hardness : Flexible

|

ULTRANANOTECH PRIVATE LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry