Fuel Cell Stack 10

Fuel Cell Stack 10 Specification

- Strength

- N/A (Mechanical strength not specified)

- Purity

- 99% (Fuel gas purity recommended)

- Hardness

- N/A (Not applicable for core operation)

- Product Type

- Proton Exchange Membrane (PEM) Fuel Cell Stack

- Material

- Graphite, Platinum, Composite Housing

- Alloy

- Non-alloy; Specialized fuel cell materials

- Shape

- Rectangular stack

- Moisture

- Sensitive to high moisturekeep dry

- Chemical Composition

- Platinum catalyst, Graphite plates, Polymer Electrolyte Membrane (PEM)

- Application

- Education, Research, Demonstration, Portable Power

- Dimension (L*W*H)

- Approx. 200mm x 100mm x 90mm

- Color

- Metallic Silver & Black modules

- Rated Voltage

- 6V-8.4V DC

- Operating Temperature Range

- 5°C to 40°C

- Start-up Time

- < 1 minute

- Fuel Type

- Hydrogen (H2)

- Connection Type

- Wired output terminals

- Humidification

- Self-humidified

- Cooling Method

- Air cooled; passive

- Cell Number

- 10 cells in series

- Rated Power Output

- 10W

- Efficiency

- Up to 50% electrical efficiency

- Service Life

- Typical 1,000 hours depending on operating conditions

- Stack Weight

- Approx. 480g

Fuel Cell Stack 10 Trade Information

- Payment Terms

- Paypal

- Delivery Time

- 15 Days

- Main Export Market(s)

- North America, South America, Eastern Europe, Middle East, Central America, Asia

- Main Domestic Market

- All India

About Fuel Cell Stack 10

Brand: H-TECEducation

Product Code: 1071040

Description:

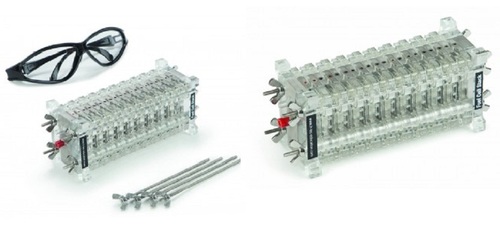

H-TEC's Fuel Cell Stack 10 is a modular fuel cell stackwith 10 cells that are easy to add or remove. The Fuel Cell Stack 10 allowsvoltages between individual cells to be measured. The stack is deliveredfully assembled.

About the PEM Fuel Cell Process

Hydrogen gas is oxidized within a fuel cell. In theprocess, the chemical energy stored in the hydrogen gas is converted directly,i.e. without combustion, to electrical energy. This process takes placein the heart of the fuel cell, the Membrane Electrode Assembly (MEA).

The MEA comprises two electrodes (cathode: oxygen sideand anode: hydrogen side) and the Proton Exchange Membrane (PEM). The PEMis a special plastic film which is permeable to protons but which presents abarrier to electrons.

Hydrogen gas is split by catalysis into electrons andprotons in the fuel cell. Due to the chemical imbalance created, theprotons (cations) diffuse through the PEM. The resulting potentialdifference can be tapped on the electrodes in the form of a no-load voltage. As soon as an electric circuit is connected to the fuel cell, the surpluselectrodes flow to the cathode, where they combine with the oxygen and theprotons to form water (H2O). The water produced escapes viathe air vent in the form of water vapor.

Fuel Cell Stack 10 Features:

Modular design

Flexible power output

Single gas supply for whole stack

Easy to add or remove cells from fuelcell stacks.

Technical Specifications:

Power Per Cell: 200 mW

Total Power (10 Cells): 2 W

Generated Voltage: 0.4 - 0.96 V per cell

Electrode Area: 4cmA2 per cell

Dimensions (H x W x D): 2.4" x 7" x 2.8" (60 x 178 x 70 mm)

Weight: 15.2 oz (430 g)

Versatile Applications

Designed for use in education, laboratory research, demonstrations, and portable power solutions, the Fuel Cell Stack 10 offers flexibility for a wide range of users. Its manageable size and weight make it suitable for classroom settings, field studies, or compact power needs. Whether you are a distributor, manufacturer, or experimentation enthusiast, this stack brings clean energy principles to practical use.

Outstanding Efficiency & Fast Start-Up

With up to 50% electrical efficiency, the Fuel Cell Stack 10 optimizes hydrogen consumption while delivering reliable performance. Its start-up time is remarkably short-less than a minute-allowing for rapid deployment in research and demonstration scenarios. The self-humidified design supports ease of operation, reducing the need for complex water management systems.

Reliable Build and Simple Integration

Built with a robust combination of platinum catalyst, graphite plates, and a polymer electrolyte membrane, the stack is designed for both stability and durability. Its wired output terminals ensure straightforward integration with electronic setups, and the metallic silver and black housing adds a professional, modern appearance. Passive air cooling further simplifies maintenance and setup.

FAQ's of Fuel Cell Stack 10:

Q: How do I properly operate the Fuel Cell Stack 10 for optimal performance?

A: To achieve optimal performance, use high-purity (99%) hydrogen as fuel and maintain the ambient temperature within the 5C to 40C range. Ensure the stack is kept dry as it is sensitive to high moisture. Connect the wired output terminals to your load, and expect power delivery within 1 minute of start-up.Q: What are the main benefits of using the Fuel Cell Stack 10 in educational and research settings?

A: The stack provides a hands-on demonstration of hydrogen fuel cells, offering real-world learning opportunities for students and researchers. Its efficient, clean power output and simple operation make it ideal for experimental setups, providing insights into renewable energy technologies.Q: When should I replace or service the fuel cell stack?

A: Replacement or servicing is typically recommended after 1,000 hours of operation; however, this can vary depending on operating conditions. Regular inspections for moisture, corrosion, or performance degradation can help maximize service life.Q: Where can the Fuel Cell Stack 10 be effectively utilized?

A: It is well-suited for use in laboratories, classrooms, portable power applications, and demonstration projects in the United States. Its compact build and flexible integration allow deployment in various practical scenarios where hydrogen power is desired.Q: What is the correct process for installing and connecting this fuel cell stack?

A: Install the stack on a stable, dry surface to prevent moisture damage. Connect the hydrogen supply following safety protocols and use the wired output terminals to attach your electrical load. No additional humidification or complex cooling systems are required due to its self-humidified and air-cooled design.Q: How should I store the Fuel Cell Stack 10 when not in use?

A: Store the unit in a cool, dry area, away from high humidity or moisture to protect sensitive components. Disconnect all supplies, and, when possible, cover the stack to prevent dust accumulation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Fuel Cell Stacks Category

GreenHub 2 PRO 500

Product Type : Other, Smart Power Hub

Moisture : Nil

Material : Aluminum and polymer

Application : Other, Industrial power management

Purity : 99.99%

Alloy : Aluminum composite

Flex-Stak Electrochemical Cell

Product Type : Other, Electrochemical Cell Stack

Moisture : Moistureresistant/Corrosionresistant materials used

Material : Polycarbonate plates, Platinum electrodes, Carbon felt, Membrane (Nafion/PEM)

Application : Other, Fuel cell research, water electrolysis, electrochemical testing, educational demonstration

Purity : High (Electronic Grade Components)

Alloy : None (Nonmetallic and platinumcoated components)

Syringe (Without Needle)

Product Type : Other, Medical syringe without needle

Moisture : Moistureproof packaging

Material : Polypropylene (PP), synthetic rubber gasket

Application : Other, Liquid medication administration, fluid withdrawal, laboratory use, irrigation

Purity : Sterile, nontoxic, pyrogenfree

Alloy : Not applicable (nonmetallic)

300W Liquid Cooled PEM Fuel Cell Stack

Product Type : Other, Proton Exchange Membrane (PEM) Fuel Cell Stack

Moisture : Stack must remain adequately humidified

Material : Polymer Electrolyte Membrane, Graphite or Metal Bipolar Plates, Platinum Catalyst

Application : Other, Backup power, Laboratories, Educational Demonstrations, Portable Power, Research

Purity : High purity hydrogen required (>99.99%)

Alloy : No external alloy; stack employs catalystcoated membrane and graphite/metal flow plates

|

ULTRANANOTECH PRIVATE LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry